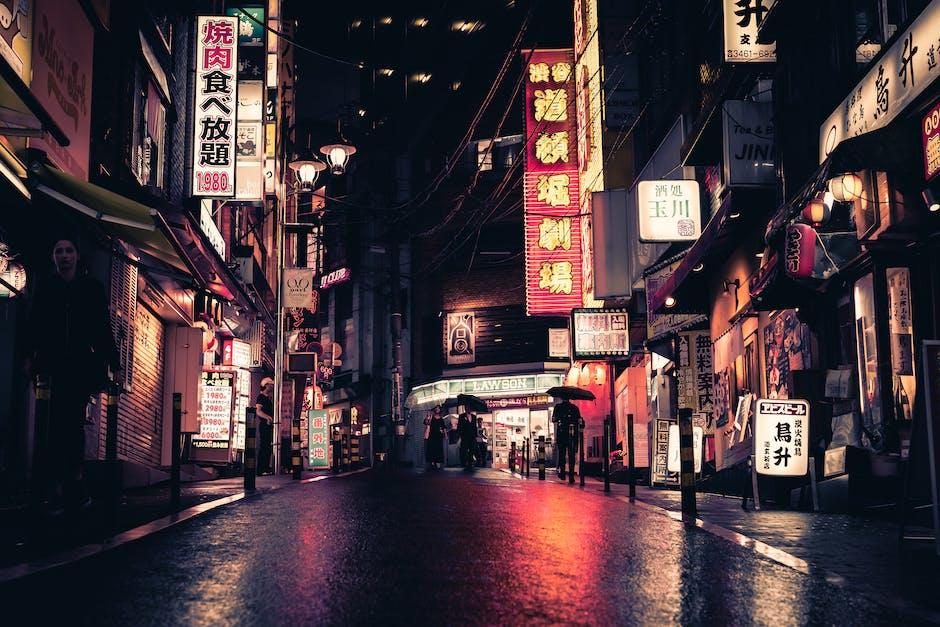

What is neon?

Neon Signs Have Been Around For Ages. What Is The Process For Making Neon Tubing Gases. Neon is a color that can appear bright red, orange, yellow, or green. It is created by excited electrons in gas molecules. Neons were used centuries ago to decorate buildings with colored lights. Modern devices use neons to display information (e.g., for alertness) and as signaling mechanisms. For example, you might see flashing neon signs advertising a business’s opening hours or warning signals when someone needs emergency medical assistance.

Neon was first produced commercially in 1859. A chemist by the name of Thomas Edison invented methods to put these gases into practical usage. He also improved the efficiency of production using lower temperatures. His improvements allowed the manufacture of brightly-colored gases at a reasonable price. Soon he found new uses for them in lighting and other applications.

Edison also developed processes to create different hues of light from incandescent lamps, which worked until the introduction of electric bulbs made by Joseph Swan in 1895.

How is neon made?

In its most common form, neon consists of two gases contained in separate tubes. The gases are helium (He) and one or more nitrogen compounds (N). The He gas is ionized to create ions that emit light as they move through the N gas.

Several types of neons are used in industry, including fluorescent, plasma, and thermoelectric. A variety of materials can be processed using this technique, from plastics to metals.

Neon production has been described as being “robust”. Methods of manufacturing include chemical vapor deposition, thermal evaporation, electropolishing, and laser ablation.

What are the different types of neon?

Neon Signs Have Been Around For Ages. What Is The Process For Making Neon Tubing Gases. Neon is made through vaporization of metal salts, which then ionize to form gases. The amount of gas formed depends on many factors, including temperature and pressure. There are six main types of neon (the number 6 because it has six points):

Neon-argon, neoprene, neutral, nitrogen, oxygen, silica, and tantalum.

These various gases have different properties — most notably, density. It’s very important for artists to understand how these differences affect how they use each type of neon.

For example, electricians need knowledge of electrical differences between these two gases in order to properly install neon lights.

How do I use neon?

Neon is a gas that can be used in plumbing systems to color water when it comes into contact with acids. It’s also been used for signage, but this application is becoming less common as LEDs improve.

Neon was developed in the 20th century, though it has been known about for centuries. In the 19th century, people started using caustic chemicals to color drinking water without having to add any dye to it. Over time, these chemicals became more widely available and were even manufactured at home. They were just too dangerous to sell in homes.

Fortunately, scientists have safety protocols for such gases. The most commonly used protocol is to replace oxygen with carbon dioxide (CO2) during combustion. CO2is safer than oxygen because pure nitrogen atoms are very stable, but molecules of oxygen are much smaller and easier to handle.

What is neon tubing?

Neon gas is used to create colored gases that are used in birthday parties, special events, and community gatherings. These can be single colors or multiple colors separated into different gases.

Neon comes in two forms: solid and liquid. The difference between them is how they are made.

When you get your hands on either form of neon, it’s important to know what type it is. Both forms were described by Dr. Hubert Knapen in an article called A New Understanding Of Neons And Their Significance In Society.

He defined three types of neons:

1) The static neon, which is made from ethereal oil with added gas molecules suspended inside.

2) The inert neon, where no gas is dissolved and there is no free-flowing gas phase. This was the first neon produced. It has been used as window decoration and advertising sign filler.

3) The true neon, also known as flowing neon, refers to both the gaseous state of the fluid and the continuous flow of gas particles.

4) The flashing neon represents a self-contained device that produces electric current using internal batteries. It may be set in motion through the use of chemical reactions, heat (using light bulbs), or cold cathodes.

Flashing neon became popular in the United States during the 1950s and 1960s. Its popularity arose from its distinctive sound and visual appeal. Sound

How is neon tubing made?

Neon Signs Have Been Around For Ages. What Is The Process For Making Neon Tubing Gases. There are several ways to make gas. The way that we typically make gas is by using electric discharge. This creates plasma, which can then be filtered to remove particles larger than atoms, allowing you to produce pure gases such as helium or argon. These are just two of the many available gases.

Another common method of making gas is called dissociation. In this case, molecules are broken into smaller pieces: nitrogen will break down into separate nitrogen atoms and oxygen into separate oxygen atoms. These products are sold separately or in combination with each other.

A third option is electrolysis. In this process, water is separated into hydrogen and oxygen gases through application of electricity and special chemicals. You may have seen pictures of batteries where individual cells are represented by dots of red, white, and blue plastic held together with a metal casing. Everything inside a battery is connected except for the positive and negative terminals, which are isolated within the cell.

Electrolysis works because it uses lower temperatures and simpler processes. When water is heated, its molecular structure unfolds, and it becomes more reactive. Heating water also increases the rate at which ions move around inside and outside of your body’s membranes.

What are the different types of neon tubing?

Neon is manufactured in two primary ways – cold cathode discharge (CCD) and hot cathode discharge (HCD). Both methods produce light at similar intensities, but HCD produces greater quantities of brighter lights.

Different materials are used to create the various sizes of tubes, including glass or quartz fiber reinforced plastic (FRCP), polyethylene, steel, aluminum, and carbon nanotubes.

The electrical requirements for these devices are quite low, so any type of gas will do. Common gases include helium, argon, krypton, and nitrogen.

These can be obtained from high-pressure tanks or even air compressors. The pressure must be adjusted according to the length of the tube. Longer lengths require higher pressures.

Neons usually come pre-filled with either oxygen or acetylene. This is because most appliances that use them have been designed around this composition.

But you can also fill neons with other chemicals such as ammonia/ammonia, hydrogen peroxide/hydrogen peroxide, and sodium hydrosulfide/sodium sulfide.

There are many unique applications for neon lighting, including signage, decorations, waterfalls, highlighting, photography, and more. It’s very versatile and useful.

Can I use neon to fill my glass globe?

Yes, you can! But please remember that neon is a gas at room temperature. This means it will evaporate if not filled with liquid or sealed properly.

Neon has several modes of evaporation depending on the pressure level in the container. At normal pressures (and temperatures), there’s an equilibrium between the gaseous form and solid forms of neonsmoke and neoluminescent powder.

At higher pressures, such as those found in a car engine, more gaseous neon is produced. And since less of it can be held in solution, more solids are formed. You can read more about this phenomenon here: http://www.scientificamerican.com/article/how-neon-works/

Sealing the container tightly slows down the process, but doesn’t stop it altogether. The choice of container also matters much when trying to achieve full saturation.

A clear container with a narrow opening helps keep out excess gas, providing a better user experience. Containers with wide openings allow some gases to escape, though most people don’ calll their effect “overpowered” by other devices in the area.

Can I use neon to fill my plastic tube?

Yes, you can! But here are some things to keep in mind :

Neon does not come in gas form. It comes as a liquid.

It must be vaporized (or broken down into gases). Do this carefully, as there is no quick way to do it. There are several ways; see below.

The resulting plasma will be mostly nitrogen or oxygen depending on what you want. You can then either leave it like that or convert the N/O back into liquid neon by injecting hot air into the tube.

You can also add other chemicals to alter the color of the plasma.