What is neon?

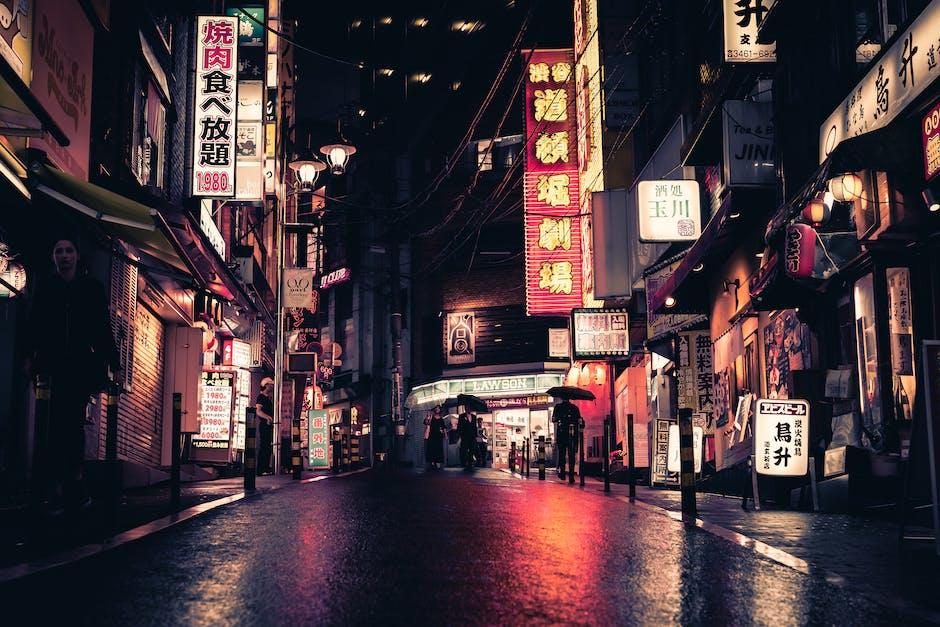

Neon Signs Have Been Around For Ages. What Is The Process For Making Neon Tubing Gases. Neon is a color that can appear bright red, orange, yellow, or green. It is created by excited electrons in gas molecules. Neons were used centuries ago to decorate buildings with colored lights. Modern devices use neons to display information (e.g., for alertness) and as signaling mechanisms. For example, you might see flashing neon signs advertising a business’s opening hours or warning signals when someone needs emergency medical assistance.

Neon was first produced commercially in 1859. A chemist by the name of Thomas Edison invented methods to put these gases into practical usage. He also improved the efficiency of production using lower temperatures. His improvements allowed the manufacture of brightly-colored gases at a reasonable price. Soon he found new uses for them in lighting and other applications.

Edison also developed processes to create different hues of light from incandescent lamps, which worked until the introduction of electric bulbs made by Joseph Swan in 1895.

How is neon made?

In its most common form, neon consists of two gases contained in separate tubes. The gases are helium (He) and one or more nitrogen compounds (N). The He gas is ionized to create ions that emit light as they move through the N gas.

Several types of neons are used in industry, including fluorescent, plasma, and thermoelectric. A variety of materials can be processed using this technique, from plastics to metals.

Neon production has been described as being “robust”. Methods of manufacturing include chemical vapor deposition, thermal evaporation, electropolishing, and laser ablation.

What are the different types of neon?

Neon Signs Have Been Around For Ages. What Is The Process For Making Neon Tubing Gases. Neon is made through vaporization of metal salts, which then ionize to form gases. The amount of gas formed depends on many factors, including temperature and pressure. There are six main types of neon (the number 6 because it has six points):

Neon-argon, neoprene, neutral, nitrogen, oxygen, silica, and tantalum.

These various gases have different properties — most notably, density. It’s very important for artists to understand how these differences affect how they use each type of neon.

For example, electricians need knowledge of electrical differences between these two gases in order to properly install neon lights.

How do I use neon?

Neon is a gas that can be used in plumbing systems to color water when it comes into contact with acids. It’s also been used for signage, but this application is becoming less common as LEDs improve.

Neon was developed in the 20th century, though it has been known about for centuries. In the 19th century, people started using caustic chemicals to color drinking water without having to add any dye to it. Over time, these chemicals became more widely available and were even manufactured at home. They were just too dangerous to sell in homes.

Fortunately, scientists have safety protocols for such gases. The most commonly used protocol is to replace oxygen with carbon dioxide (CO2) during combustion. CO2is safer than oxygen because pure nitrogen atoms are very stable, but molecules of oxygen are much smaller and easier to handle.

What is neon tubing?

Neon gas is used to create colored gases that are used in birthday parties, special events, and community gatherings. These can be single colors or multiple colors separated into different gases.

Neon comes in two forms: solid and liquid. The difference between them is how they are made.

When you get your hands on either form of neon, it’s important to know what type it is. Both forms were described by Dr. Hubert Knapen in an article called A New Understanding Of Neons And Their Significance In Society.

He defined three types of neons:

1) The static neon, which is made from ethereal oil with added gas molecules suspended inside.

2) The inert neon, where no gas is dissolved and there is no free-flowing gas phase. This was the first neon produced. It has been used as window decoration and advertising sign filler.

3) The true neon, also known as flowing neon, refers to both the gaseous state of the fluid and the continuous flow of gas particles.

4) The flashing neon represents a self-contained device that produces electric current using internal batteries. It may be set in motion through the use of chemical reactions, heat (using light bulbs), or cold cathodes.

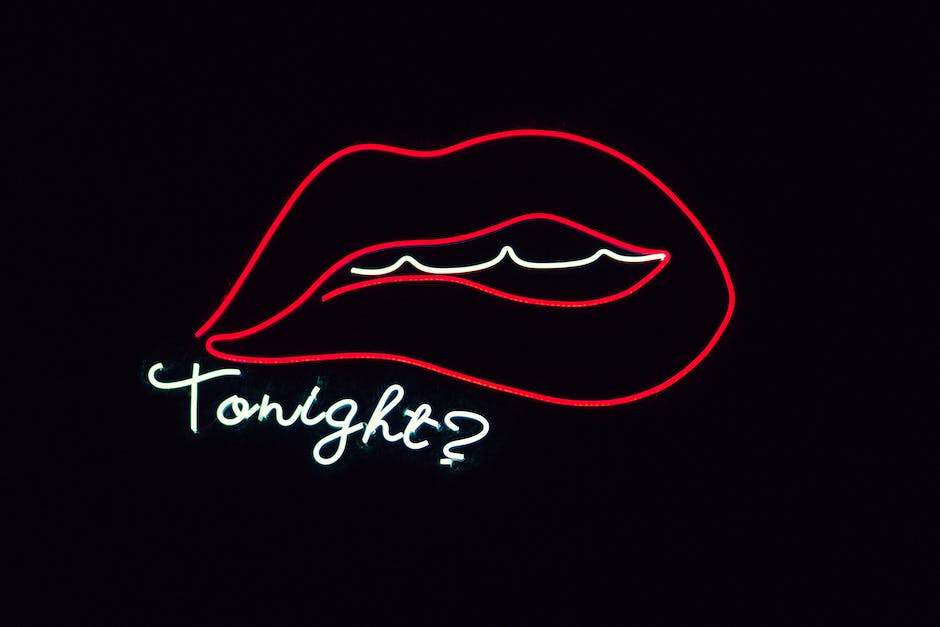

Flashing neon became popular in the United States during the 1950s and 1960s. Its popularity arose from its distinctive sound and visual appeal. Sound

How is neon tubing made?

Neon Signs Have Been Around For Ages. What Is The Process For Making Neon Tubing Gases. There are several ways to make gas. The way that we typically make gas is by using electric discharge. This creates plasma, which can then be filtered to remove particles larger than atoms, allowing you to produce pure gases such as helium or argon. These are just two of the many available gases.

Another common method of making gas is called dissociation. In this case, molecules are broken into smaller pieces: nitrogen will break down into separate nitrogen atoms and oxygen into separate oxygen atoms. These products are sold separately or in combination with each other.

A third option is electrolysis. In this process, water is separated into hydrogen and oxygen gases through application of electricity and special chemicals. You may have seen pictures of batteries where individual cells are represented by dots of red, white, and blue plastic held together with a metal casing. Everything inside a battery is connected except for the positive and negative terminals, which are isolated within the cell.

Electrolysis works because it uses lower temperatures and simpler processes. When water is heated, its molecular structure unfolds, and it becomes more reactive. Heating water also increases the rate at which ions move around inside and outside of your body’s membranes.

What are the different types of neon tubing?

Neon is manufactured in two primary ways – cold cathode discharge (CCD) and hot cathode discharge (HCD). Both methods produce light at similar intensities, but HCD produces greater quantities of brighter lights.

Different materials are used to create the various sizes of tubes, including glass or quartz fiber reinforced plastic (FRCP), polyethylene, steel, aluminum, and carbon nanotubes.

The electrical requirements for these devices are quite low, so any type of gas will do. Common gases include helium, argon, krypton, and nitrogen.

These can be obtained from high-pressure tanks or even air compressors. The pressure must be adjusted according to the length of the tube. Longer lengths require higher pressures.

Neons usually come pre-filled with either oxygen or acetylene. This is because most appliances that use them have been designed around this composition.

But you can also fill neons with other chemicals such as ammonia/ammonia, hydrogen peroxide/hydrogen peroxide, and sodium hydrosulfide/sodium sulfide.

There are many unique applications for neon lighting, including signage, decorations, waterfalls, highlighting, photography, and more. It’s very versatile and useful.

Can I use neon to fill my glass globe?

Yes, you can! But please remember that neon is a gas at room temperature. This means it will evaporate if not filled with liquid or sealed properly.

Neon has several modes of evaporation depending on the pressure level in the container. At normal pressures (and temperatures), there’s an equilibrium between the gaseous form and solid forms of neonsmoke and neoluminescent powder.

At higher pressures, such as those found in a car engine, more gaseous neon is produced. And since less of it can be held in solution, more solids are formed. You can read more about this phenomenon here: http://www.scientificamerican.com/article/how-neon-works/

Sealing the container tightly slows down the process, but doesn’t stop it altogether. The choice of container also matters much when trying to achieve full saturation.

A clear container with a narrow opening helps keep out excess gas, providing a better user experience. Containers with wide openings allow some gases to escape, though most people don’ calll their effect “overpowered” by other devices in the area.

Can I use neon to fill my plastic tube?

Yes, you can! But here are some things to keep in mind :

Neon does not come in gas form. It comes as a liquid.

It must be vaporized (or broken down into gases). Do this carefully, as there is no quick way to do it. There are several ways; see below.

The resulting plasma will be mostly nitrogen or oxygen depending on what you want. You can then either leave it like that or convert the N/O back into liquid neon by injecting hot air into the tube.

You can also add other chemicals to alter the color of the plasma.

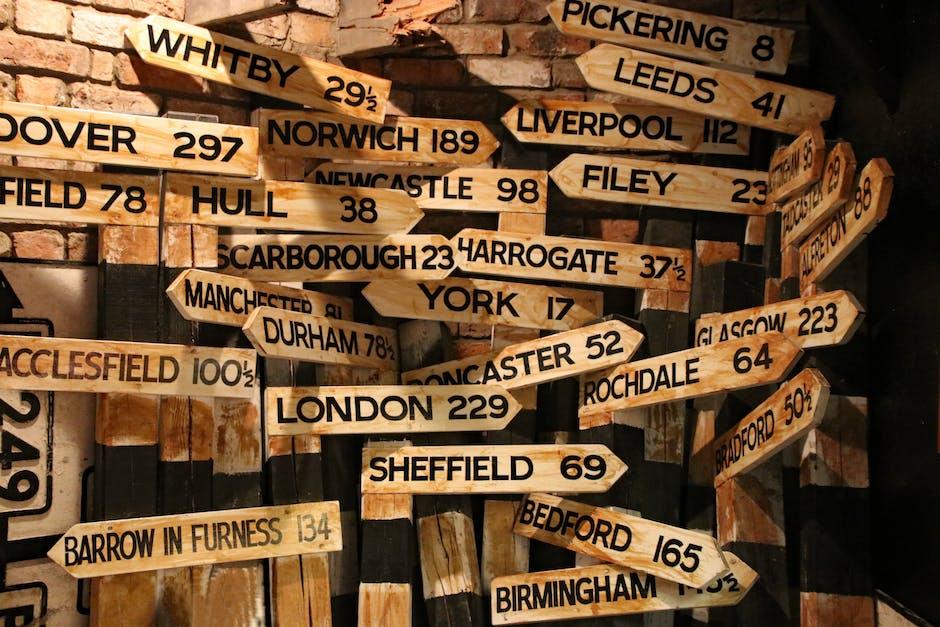

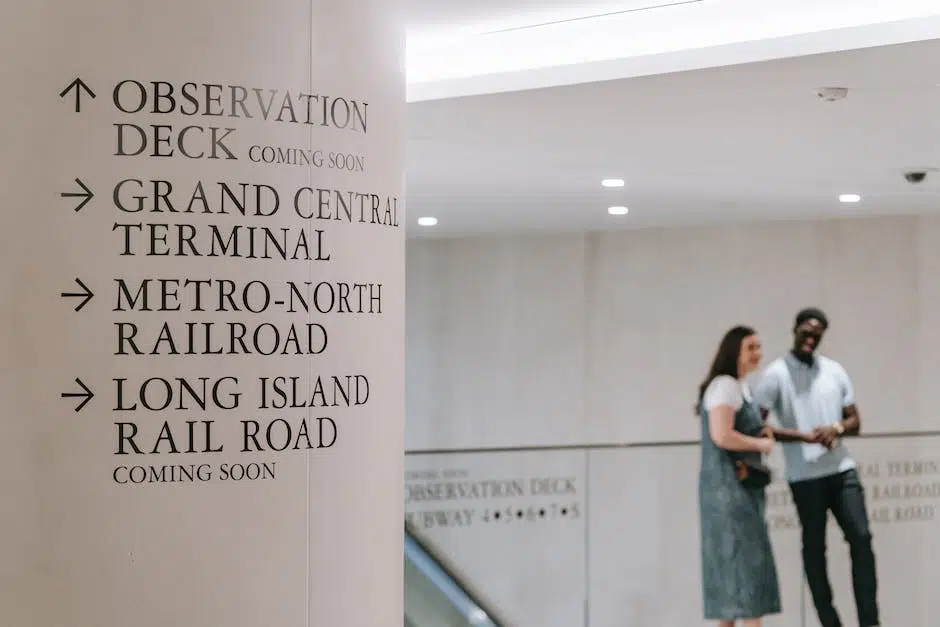

Store maps are obvious choices, but with mobile positioning technology it’s easier than ever to add directionality to your in-store signage.

Visually impaired individuals can also take advantage of directional signage to guide them through an area. For example, you could use arrows to indicate which way is best for walking or which entrance is the busiest (based on previous scans).

Directional signs can help guide customers from one area to another, helping them move more efficiently. This helps customers feel more oriented, focused, and able to pick up the pace.

This works better if there are fewer stops. Having only two options solutions results in everyone feeling like they have somewhere to go. The goal, therefore, should be that people don’t realize they’re going anywhere.

Conversational speech patterns can also reinforce this concept of direction and control. When we leave something important behind (e.g., kids’ schools, family events), we often say “now where did I put that?” Even when we aren’t explicitly thinking about lost items, we still tend to search for them after we ask a question such as ‘now where did I put that book?’

Store maps are obvious choices, but with mobile positioning technology it’s easier than ever to add directionality to your in-store signage.

Visually impaired individuals can also take advantage of directional signage to guide them through an area. For example, you could use arrows to indicate which way is best for walking or which entrance is the busiest (based on previous scans).

Directional signs can help guide customers from one area to another, helping them move more efficiently. This helps customers feel more oriented, focused, and able to pick up the pace.

This works better if there are fewer stops. Having only two options solutions results in everyone feeling like they have somewhere to go. The goal, therefore, should be that people don’t realize they’re going anywhere.

Conversational speech patterns can also reinforce this concept of direction and control. When we leave something important behind (e.g., kids’ schools, family events), we often say “now where did I put that?” Even when we aren’t explicitly thinking about lost items, we still tend to search for them after we ask a question such as ‘now where did I put that book?’

Unlike color-coded versions, directional signs can help customers in any area of your store find what they are looking for. Well-designed directionals even let people know how much certain items cost or guide them to areas of the store.

As shoppers spend more time in stores like yours, they are becoming increasingly aware of price points and product availability. By having helpful directionals, you will give customers a hand hold as well as make it easier for them to locate an item.

Many consumers don’t want to have to work very hard to get where they need to go. It takes away from their overall shopping experience if they have to think too much about every turn and corner they need to take. When shops are not organized easily, people are less likely to buy anything.

By adding useful

Unlike color-coded versions, directional signs can help customers in any area of your store find what they are looking for. Well-designed directionals even let people know how much certain items cost or guide them to areas of the store.

As shoppers spend more time in stores like yours, they are becoming increasingly aware of price points and product availability. By having helpful directionals, you will give customers a hand hold as well as make it easier for them to locate an item.

Many consumers don’t want to have to work very hard to get where they need to go. It takes away from their overall shopping experience if they have to think too much about every turn and corner they need to take. When shops are not organized easily, people are less likely to buy anything.

By adding useful  Color can make an enormous difference to how appealing your directional signage is to the eyes. When used properly, it can help you achieve better visual perception and enhanced customer experience.

All too often, people fail to differentiate between uniformity and monotony. On one hand, color should be chosen for the most part consistently; otherwise the impact would not be significant.

On the other hand, using two or more colors in combination is what makes the design unique and stands out. Such usage creates contrast and obtains interest from viewers.

Contrast is a major factor when it comes to attention getting elements. If you want people to pay closer attention to something, then it needs to have sufficient contrast with everything else around it.

Thus, while keeping objects distinct is important, so is having enough contrast between them.

Color can make an enormous difference to how appealing your directional signage is to the eyes. When used properly, it can help you achieve better visual perception and enhanced customer experience.

All too often, people fail to differentiate between uniformity and monotony. On one hand, color should be chosen for the most part consistently; otherwise the impact would not be significant.

On the other hand, using two or more colors in combination is what makes the design unique and stands out. Such usage creates contrast and obtains interest from viewers.

Contrast is a major factor when it comes to attention getting elements. If you want people to pay closer attention to something, then it needs to have sufficient contrast with everything else around it.

Thus, while keeping objects distinct is important, so is having enough contrast between them.

Another advantage of digital signage is its cost effectiveness. Business owners can achieve good returns by investing in this technology, especially when they update their signs few times a year.

According to a survey done in 2012, about 21% of companies with digital signage reported an annual budget between $1,000 and $5, 000. The average yearly expenditure was around $200 per sign.

Large businesses that need directional signage may have larger budgets. A study conducted in 2014 estimated the initial investment and maintenance requirements would be much higher if analog signage were used (i.e. costly proprietary systems or customized software).

Another advantage of digital signage is its cost effectiveness. Business owners can achieve good returns by investing in this technology, especially when they update their signs few times a year.

According to a survey done in 2012, about 21% of companies with digital signage reported an annual budget between $1,000 and $5, 000. The average yearly expenditure was around $200 per sign.

Large businesses that need directional signage may have larger budgets. A study conducted in 2014 estimated the initial investment and maintenance requirements would be much higher if analog signage were used (i.e. costly proprietary systems or customized software).

A simple way to enhance your customer experience is through directional

A simple way to enhance your customer experience is through directional  Consistency is what creates brand recognition. When customers see signage that they recognize, they know something fun or interesting will happen.

If all of

Consistency is what creates brand recognition. When customers see signage that they recognize, they know something fun or interesting will happen.

If all of

When you are planning to increase your street sign size, make sure that you have enough space around it to keep walking safely. You don’t want to add too much weight to the sign because then it won’t hold up as well. You also can’t just put more letters on the sign because that would take up too much room and reduce the overall legibility of the sign. Instead, look into re-letterizing the sign or using an offsite letter storage system like those provided by OnlineLetterStore.com. Both of these will give you extra height while keeping the solid footing secure. Plan for additional maintenance. Can I Increase The Size Of My Street Sign Without Affecting The Footing? Just because you paid to have someone write your message in big, bold letters doesn’t mean they took care of it properly. Make sure to check out any nearby signs for cracks or powdery deposits that could indicate damage. If you notice anything strange, get new ones immediately! Disclaimer: This article is for informational purposes only. The information herein should not be used as medical advice nor does it constitute a diagnosis or treatment plan for any condition. Reader Interactions Comments Hi there! Great info here 🙂 Just wanted to mention something about powdery deposits on your street signage – this is totally normal! It happens when moisture gets trapped under the plastic surface, which allows bacteria to grow and cause a reaction with the paint.

When you are planning to increase your street sign size, make sure that you have enough space around it to keep walking safely. You don’t want to add too much weight to the sign because then it won’t hold up as well. You also can’t just put more letters on the sign because that would take up too much room and reduce the overall legibility of the sign. Instead, look into re-letterizing the sign or using an offsite letter storage system like those provided by OnlineLetterStore.com. Both of these will give you extra height while keeping the solid footing secure. Plan for additional maintenance. Can I Increase The Size Of My Street Sign Without Affecting The Footing? Just because you paid to have someone write your message in big, bold letters doesn’t mean they took care of it properly. Make sure to check out any nearby signs for cracks or powdery deposits that could indicate damage. If you notice anything strange, get new ones immediately! Disclaimer: This article is for informational purposes only. The information herein should not be used as medical advice nor does it constitute a diagnosis or treatment plan for any condition. Reader Interactions Comments Hi there! Great info here 🙂 Just wanted to mention something about powdery deposits on your street signage – this is totally normal! It happens when moisture gets trapped under the plastic surface, which allows bacteria to grow and cause a reaction with the paint. Changing or adding to your street sign is not as difficult as you might think! In fact, it is quite simple if you know what steps to take. Most municipalities have an advertising division that handles this for you. They handle all the paperwork involved in changing or putting up

Changing or adding to your street sign is not as difficult as you might think! In fact, it is quite simple if you know what steps to take. Most municipalities have an advertising division that handles this for you. They handle all the paperwork involved in changing or putting up The next thing you will need to do is determine if you are allowed to increase your street sign’s height or not, according to city laws. Most municipalities require you to have a permit before going up any signage heights, especially outside buildings where people walk and use the road. This includes limiting it to 75-feet high, which is almost two stories in some cases! This is why it is important to know what regulations exist so that you don’t violate them by taking too much time to get permission first, as well as making sure you aren’t infringing on anyone else’s rights. City officials may ask you for proof of insurance when giving you the permit, just to make sure nothing happens to someone or something down below.

The next thing you will need to do is determine if you are allowed to increase your street sign’s height or not, according to city laws. Most municipalities require you to have a permit before going up any signage heights, especially outside buildings where people walk and use the road. This includes limiting it to 75-feet high, which is almost two stories in some cases! This is why it is important to know what regulations exist so that you don’t violate them by taking too much time to get permission first, as well as making sure you aren’t infringing on anyone else’s rights. City officials may ask you for proof of insurance when giving you the permit, just to make sure nothing happens to someone or something down below. Changing the size or shape of your driveway or parking lot exit is one way to increase foot traffic at your business, but you need to make sure that your street signs can handle it! If you’re looking to draw more attention to your business, then adding some decorations to serve as street signs is an excellent solution. Many people start buying plastic street signs with their businesses printed on them so they can be placed in their own yard or outside of the business property line. However, these types of signs are not designed to hold up under heavy use either. They will begin to peel off or break down very quickly! Business owners who want strong exposure should look into investing in solid, weather resistant street signs. These cost slightly more, but are much better quality than those which only have special designs on them. We recommend talking to professionals about signage for your business, and making sure you know what brands are well-supported before spending money on anything else.

Changing the size or shape of your driveway or parking lot exit is one way to increase foot traffic at your business, but you need to make sure that your street signs can handle it! If you’re looking to draw more attention to your business, then adding some decorations to serve as street signs is an excellent solution. Many people start buying plastic street signs with their businesses printed on them so they can be placed in their own yard or outside of the business property line. However, these types of signs are not designed to hold up under heavy use either. They will begin to peel off or break down very quickly! Business owners who want strong exposure should look into investing in solid, weather resistant street signs. These cost slightly more, but are much better quality than those which only have special designs on them. We recommend talking to professionals about signage for your business, and making sure you know what brands are well-supported before spending money on anything else. The next time you are driving down a highway, there is an easy way to check if your current street signs are too small. You can test it by looking at the number beside the street name. The number in front of the street should be longer than what it currently is. For example, if your street had a one-mile road length, then its number should be more like 1 mile as opposed to how it is now which is only 50 feet.

The next time you are driving down a highway, there is an easy way to check if your current street signs are too small. You can test it by looking at the number beside the street name. The number in front of the street should be longer than what it currently is. For example, if your street had a one-mile road length, then its number should be more like 1 mile as opposed to how it is now which is only 50 feet. The next step in increasing your driveway width is to find an adequate replacement for your current street signage. These new signs are typically made out of plastic or metal and can be purchased from any number of vendors online or through local sellers. Some things to look out for include if it’s painted on well and uses UV resistant paint, if it’s sturdy and doesn’t feel cheap, and whether it’s reversible so you don’t have to buy another one later. Can I Increase The Size Of My Street Sign Without Affecting The Footing? A lot of people use yard signs that they get mounted onto a wooden frame which works great! However, this isn’t necessary as most companies make their own frames now. You want to make sure yours is solid and won’t break easily.

The next step in increasing your driveway width is to find an adequate replacement for your current street signage. These new signs are typically made out of plastic or metal and can be purchased from any number of vendors online or through local sellers. Some things to look out for include if it’s painted on well and uses UV resistant paint, if it’s sturdy and doesn’t feel cheap, and whether it’s reversible so you don’t have to buy another one later. Can I Increase The Size Of My Street Sign Without Affecting The Footing? A lot of people use yard signs that they get mounted onto a wooden frame which works great! However, this isn’t necessary as most companies make their own frames now. You want to make sure yours is solid and won’t break easily. After you have picked your final design, You will need to connect your newly acquired street sign to an electrical source. This can be done by either connecting it to a power outlet or through a cable that plugs into a portable device such as a smartphone or computer. Power outlets typically use two round prongs that fit in receptacles with two flat surfaces. Make sure to measure twice before buying enough cables to meet the requirements for your

After you have picked your final design, You will need to connect your newly acquired street sign to an electrical source. This can be done by either connecting it to a power outlet or through a cable that plugs into a portable device such as a smartphone or computer. Power outlets typically use two round prongs that fit in receptacles with two flat surfaces. Make sure to measure twice before buying enough cables to meet the requirements for your